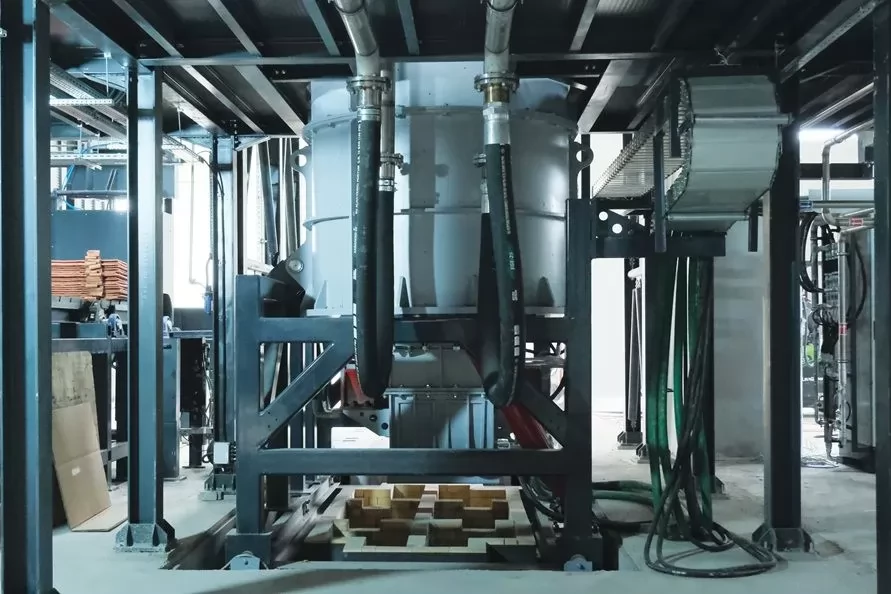

Efficient Copper Casting with Channel Induction Furnaces

Channel induction furnaces improve energy efficiency, quality, and sustainability in copper casting processes. Discover their benefits for modern production.

What Are Channel Induction Furnaces?

Channel induction furnaces are advanced heating systems designed to quickly and uniformly heat copper and its alloys. Compared to traditional furnaces, they consume less energy and provide continuous, reliable production.

Advantages of Channel Induction Furnaces

1. Energy Efficiency

Channel furnaces heat copper quickly and evenly, minimizing energy consumption. Achieving high temperatures with less energy reduces overall production costs.

2. Increased Production Capacity

Continuous heating and controlled processes enable uninterrupted production, even in large-scale operations. This significantly improves efficiency and output.

3. Improved Product Quality

Uniform temperature distribution reduces the risk of cracks or voids in the copper. This ensures products meet high-quality standards.

4. Sustainable and Environmentally Friendly Production

By consuming less energy, channel furnaces lower the carbon footprint of production. Eco-friendly processes support sustainability while reducing operational costs.

Contribution to Production Processes

These furnaces ensure continuity on production lines and reduce the need for manual intervention. They minimize material losses, increase process reliability, and lower labor costs.

Conclusion: Setting a New Standard in Modern Copper Casting

Channel induction furnaces are an indispensable technology for modern copper casting facilities, enhancing both efficiency and product quality. Their energy-saving and environmentally friendly advantages make them a key component of sustainable industrial production.